Definition – The air oil separator is a filter like part which separates the oil from the compressed air.Oil separator filter is installed inside the oil separator vessel.

Function – During compression oil is injected to lubricate, seal and absorb the heat of compression, then what comes out of the compressor element is a mixture of compressed air and oil. The oil separator separates the oil from the air as the oil needs to stay inside the compressor to keep it lubricated while the compressed air needs to exist the compressor, free of oil.

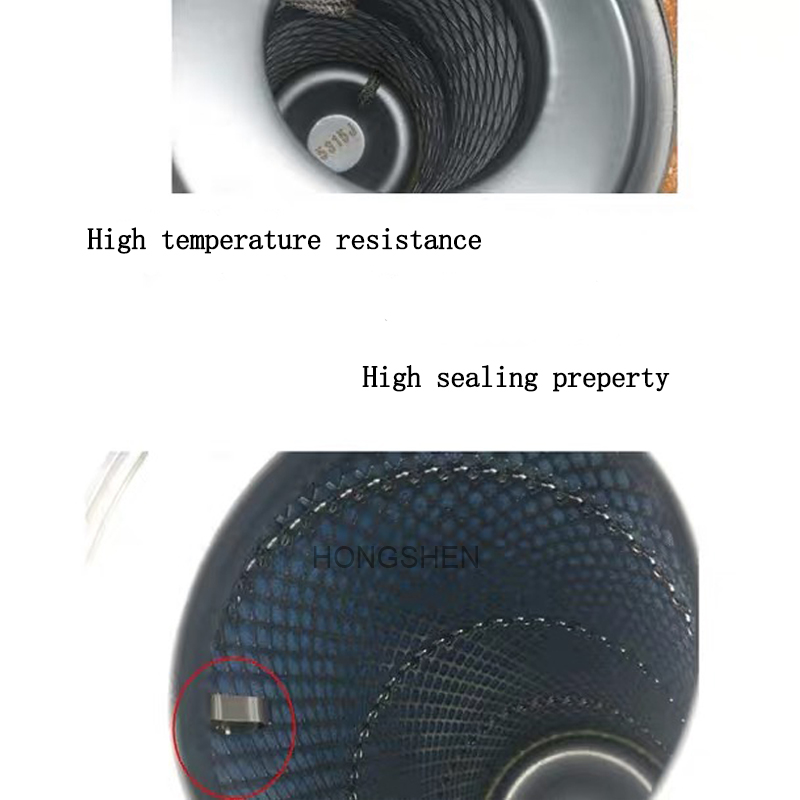

Air Compressor air oil separator is the main part to control compressed air quality,high quality air oil separator no only ensure the air compressor high efficiency working,also long life service.The gas from air compressor motor contains lubricant,large oil droplets is easy to separate when it through the air oil separator tank,but the small oil droplets(under 1um particles)have to filtering by air oil separator micro glass fiber .The oil droplets are filtered by filter materials transform to big oil droplets,in the case of gravity,oil droplets gathering in the bottom side of separator element and returns to the airend lubricating system by oil return tube,ensure the air compressor belched out clean and non-oil compressed air.The solid particles filtered in the filtering materials and caused the oil separator element pressure increased,once the differential pressure up to 0.08~.1mpa,the separator element have to replace otherwise it will increased the compressor cost.

The harm of separator element overdue using

1,bad filtration and compressed air quality couldn’t achieve using standard,it caused abnormal operation of the equipment or passing rate of products decreased.

2,pressure increased after clogging,caused the outlet pressure and machine energy consumption increased thus increased the product cost.

Air oil separator function:

To filter the air compressor lubricating metal particles and impurities,ensure the main engine lubricant is clean and protect the engine operation.

How does an Air Oil separator works ?

Most of the oil is separated by a centrifugal force. The air-oil mixture enters the separator vessel at an angle so most of the oil is pushed outside and drops down into the oil vessel. Usually, there is a splash plate installed that prevents the air-oil mixture from hitting the separator filter directly, 85% of the oil is separated this way. The remaining 15% exists the compressed air as small droplets and mist. As this oily compressed air flows through the separator filter, the small droplets combine and form large drops until they fall and collect at the bottom of the separator filter, this oil is then sucked up and removed by the scavenge line.

Regular checks when you have oil carryover problems and suspect it is the oil separator ?

1,Should there be a lot of oil inside the oil separator, then the scavenge line is faulty.

2,Should the oil level at the base of the element be higher than five centimetres this will indicate that the separator is starting to saturate, meaning that the filter media is filling up with oil.

3,Should the separator feel heavy, looks dark in colour and saturated from the bottom to the top then it is really time to replace the oil separator.

4,This can only be measured when the compressor is running loaded, the differential pressure can be checked and should not be above 0.2 to 0.3 bar under load.

Please note that above points can only be checked when the oil separator is removed from the separator vessel.

How to repair or replace an oil separator ?

Open the separator vessel and replace the separator filter.

Ensure the new filter is the same size as the old one, should it be longer or shorter be sure to adjust the length of the scavenge pipe.

Ensure to use provided gaskets, as these contain a mental conductor, this prevents static electricity from building up in the separator, which could cause sparks, which could also lead to a separator vessel

explosion .

Contact: Mousika

Phone: 13728310521

E-mail: mousika_hkhc@163.com

Add: No3,Lane 5,Guanting East street,Yongtai village ,Yongping Street,Baiyun area,Guangzhou,510440,China